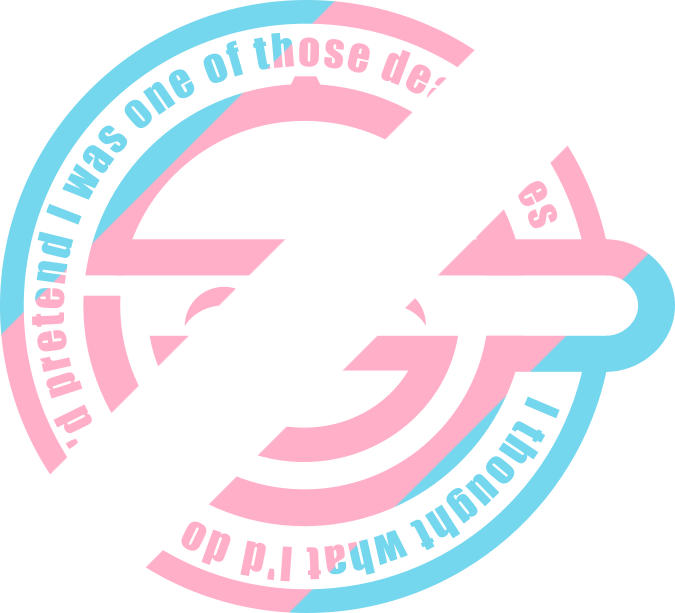

Having bought screws just the other day, I was exasperated at how I could not figure out how long the screw actually is between my thumb and finger cause they’re in a sealed box.

But I knew exactly which material they have been plated/hardened with. 🤷

So, I understand why you posted this.

And the info about the (pre) drilling is just 😙👌

Generally screw length is measured by how deep it will go into the material. For instance a countersunk screw would be measured from the top of the head to the end of the screw. A pan head screw would be measured from the bottom of the head to the end of the screw.

Yes, no need to guess or to do test holes to see which drill size is correct

While I’m certainly no handyman, I usually just hold the drill bit to the screw to find one slightly smaller, then just use that.

I am fairly handy and have never had that method fail for anything except screwing into thick metal, in which case I’m tapping threads and using a bolt anyway.

Fucking love that

What is pozi compatible recess?

Pozidrive is a type of screwhead like Phillips head. Its shape is similar to a Phillips head, but it has indentations at the inside corners of the “cross” (the black silhouette of the screwhead on the OP packaging shows this better than I can explain it). Pozidrive screwdrivers have lobes that slot into these indentations. IIRC, pozidrive is supposed to have less chance of camming out of the screw and stripping the head than Phillips.

Pozi compatible recess means that you’ll be able to use a pozidrive screwdriver with these screws.

As a guy who rides Japanese motorcycles, giv me JIS, or give me death.

deleted by creator

It’s a scheme

Except for the German translation, which was either made by an idiot or Google translate…

I suspect that they’re all like that.

Surely is an einzelfaden lol

Dutch as well. I don’t think “enkeldraad” is a good way to translate “single thread” when talking about screw threads.

A bricklayer will try to use these with a hammer.

Huh, that’s pretty normal around here. But the German translation of “thread” is wrong. Literally unusable screw, light it on fire immediately.

In spanish it says it is a yellow single thread, no mention to screws

Sideways on the corner of the box, “tornillo multiusos”

I love how evocative the word tornillo is. In my mind it translates as “little twisty thing”.

Wrong word for thread though. Should be rosca

In German it should be Gewinde.

Removed by mod

I am a complete amateur, but the box fits my experience.

If you use same size drill as the plug, the whole will be too big, and the plug is not fitting tight and firm enough, so the screw will just rotate the plug in the whole.

Especially in old cement you need to be careful not to use too big a drill.Removed by mod

I only see length on that box???

What the fuck use is that?

Also the image shows th plug sticking out, and as (2)40 mm, with something else that is unclear to me as (2)35mm.

Personally by the quality shown, the illustrations are useless to me.The plug is 6mm meant for 4-5 mm screws, there is no indication of drill sizes that I can se.

There is also a measure on the right of (2) 12.5 mm which is completely unclear what is for?

I don’t get you point.

In the old days we got rawlplugs in plastic holders, with holes for the size of drill to be used. The hole for the drill is ALWAYS smaller than the plug (obviously for the previously mentioned reasons)Rawl brand have these notes on the plastic, which I think is neat.

Brown plug, 7mm hole, 5-6mm screw.

Even a little gauge to go with it.

Removed by mod

They’re mixing up their metric and imperial sizes. These are from Forgefix, which are a British company. Many British people aged about 55 and over tend to still use imperial sizes for some things.

So it’s not 6-8mm, but "the size of wall plug for 6-8 gauge screws, which are 3.5mm - 4mm screws in metric.

Strangely, if you buy a multipack of masonry bits, they give you 3, 4, 6, 8, 10mm bits. Some brands of wall plugs tend to use 5.5mm, 6.5mm, 7mm. It is a conspiracy!

Your options are:

- Use a smaller drill bit and wiggle it, just a little bit

- Use a larger drill bit and pack it out with a shim/matchstick/chopped off half-a-wallplug

- Individually buy the masonry bits which correspond to the plugs

- Buy a different brand of wall plug, which uses 6mm or 8mm bits

The internet has ruined me because I looked at the part code and snickered.

Removed by mod